An In-depth Look at PVC

Abstract: This article provides a comprehensive overview of Polyvinyl Chloride (PVC), covering its production process, properties, applications, environmental impact, and future prospects. It also includes visual aids such as pictures and videos to enhance understanding and concludes with a set of frequently asked questions and answers.

I. Introduction

Polyvinyl Chloride, commonly known as PVC, is one of the most widely used synthetic polymers in the world. It has a unique set of properties that make it suitable for a vast array of applications, ranging from construction and automotive industries to healthcare and consumer products.

II. Production Process

The production of PVC begins with the polymerization of vinyl chloride monomer (VCM). This process can be carried out using different methods, such as suspension polymerization, emulsion polymerization, and bulk polymerization.

- Suspension Polymerization

In suspension polymerization, VCM is suspended in water with the help of stabilizers and initiators. The reaction takes place in a reactor under controlled temperature and pressure conditions. The resulting PVC particles are spherical and have a relatively uniform size distribution.

- Emulsion Polymerization

Emulsion polymerization involves the use of emulsifiers to disperse VCM in water as tiny droplets. This method produces PVC with a smaller particle size and is often used for applications where a finer particle size is required, such as in the production of PVC latex for coatings.

- Bulk Polymerization

Bulk polymerization is carried out without the use of a solvent or dispersing medium. It requires careful control of the reaction conditions to prevent overheating and ensure the quality of the PVC produced. This method is less commonly used due to its complexity and the potential for safety issues.

III. Properties of PVC

PVC possesses several properties that contribute to its widespread use.

- Mechanical Properties

PVC has good tensile strength and rigidity, which makes it suitable for applications where structural integrity is important. It can be modified with the addition of plasticizers to improve its flexibility and impact resistance. For example, in the production of vinyl flooring, plasticizers are added to make the material more flexible and comfortable underfoot.

- Chemical Resistance

PVC is highly resistant to many chemicals, including acids, bases, and salts. This property makes it ideal for use in chemical processing plants, where it is used for pipes, tanks, and other equipment.

- Electrical Insulation

PVC is an excellent electrical insulator, which is why it is widely used in the electrical and electronics industries for wire and cable insulation.

- Weather Resistance

When properly formulated, PVC can exhibit good resistance to weathering, including UV radiation and temperature changes. This makes it suitable for outdoor applications such as siding, window frames, and roofing membranes.

IV. Applications of PVC

The versatility of PVC has led to its use in numerous industries and applications.

- Construction Industry

- Pipes and Fittings: PVC pipes are widely used for water supply, drainage, and sewage systems due to their corrosion resistance, durability, and ease of installation.

- Window Frames and Doors: PVC window frames and doors offer good insulation properties, low maintenance requirements, and a wide range of design options.

- Siding and Roofing: PVC siding and roofing membranes provide protection from the elements and enhance the aesthetic appeal of buildings.

- Automotive Industry

- Interior Trim: PVC is used for car interiors, including dashboards, door panels, and seat covers, due to its flexibility and ability to be molded into various shapes.

- Wire and Cable Insulation: As mentioned earlier, PVC is used to insulate electrical wires and cables in automobiles.

- Healthcare Industry

- Medical Devices: PVC is used in the production of medical tubing, blood bags, and other medical devices due to its biocompatibility and sterilizability.

- Hospital Flooring: Vinyl flooring made from PVC is commonly used in hospitals and healthcare facilities for its ease of cleaning and durability.

- Consumer Products

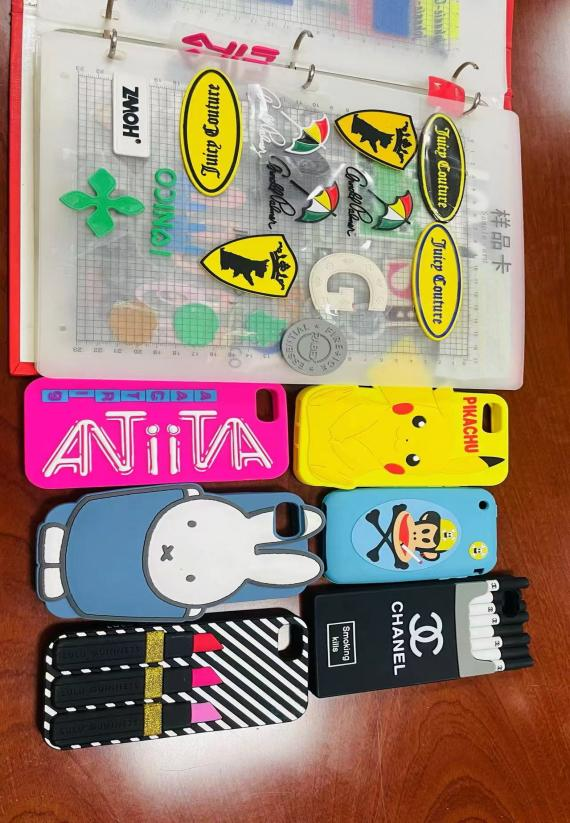

- Toys: Many children’s toys are made from PVC due to its low cost and ability to be molded into various shapes and colors.

- Packaging: PVC is used for blister packaging and shrink-wrap films to protect and display consumer products.

V. Environmental Impact and Sustainability

The production and disposal of PVC have raised concerns about its environmental impact.

- Production Emissions

The production of PVC involves the use of chlorine, which can lead to the release of dioxins and other harmful pollutants if not properly controlled. However, modern production processes have implemented measures to reduce these emissions significantly.

- End-of-Life Disposal

PVC is not biodegradable, and improper disposal can lead to environmental pollution. Recycling of PVC is an important aspect of reducing its environmental footprint. Mechanical recycling, where PVC waste is ground and reprocessed into new products, and feedstock recycling, which converts PVC back into its monomer or other useful chemicals, are two common methods of recycling.

VI. Future Prospects

Research and development efforts are focused on improving the properties of PVC and making its production and use more sustainable.

- New Additives and Formulations

Scientists are exploring the use of new additives and formulations to enhance the performance of PVC, such as improving its heat resistance, flame retardancy, and mechanical properties without sacrificing its other desirable characteristics.

- Biodegradable Alternatives

There is also ongoing research into the development of biodegradable alternatives to PVC, although currently, no material has been able to fully replace PVC in all its applications.

VII. Frequently Asked Questions

- Is PVC safe for use in food packaging?

Yes, when produced and used in accordance with strict regulations, PVC can be used for food packaging. However, certain additives used in PVC may pose a risk if they migrate into the food, so proper testing and quality control are essential.

- How can I tell if a product is made from PVC?

Look for recycling codes or markings on the product. PVC is often marked with the number 3 inside the recycling symbol. Additionally, its characteristic smell and feel can sometimes help identify it.

- What are the main differences between rigid and flexible PVC?

Rigid PVC has a higher degree of polymerization and contains fewer plasticizers, resulting in greater strength and rigidity. Flexible PVC, on the other hand, has more plasticizers added to make it more pliable and suitable for applications where flexibility is required, such as in hoses and flexible tubing.

- Can PVC be recycled with other plastics?

It is not recommended to recycle PVC with other plastics as it can contaminate the recycling stream and affect the quality of the recycled material. PVC should be separated and recycled through specialized processes.

- How does the price of PVC compare to other plastics?

PVC is generally more cost-effective compared to many other plastics, which is one of the reasons for its widespread use. However, its price can fluctuate depending on factors such as raw material availability, production costs, and market demand.

VIII. Conclusion

PVC is a remarkable polymer with a wide range of applications that have significantly impacted various industries. While its environmental impact poses challenges, ongoing efforts in research and development are aimed at making it more sustainable. Understanding the properties, production process, and applications of PVC is crucial for both consumers and industries alike as we strive to balance the benefits and drawbacks of this versatile material.

Article Brief: This comprehensive article delves into the world of PVC. It begins with an introduction to PVC and then details its production processes, including suspension, emulsion, and bulk polymerization. The properties like mechanical strength, chemical resistance, and electrical insulation are explored, followed by its extensive applications in construction, automotive, healthcare, and consumer products. The environmental impact and sustainability aspects are also discussed, along with future prospects. Finally, a set of FAQs provides quick answers to common queries about PVC. Overall, it offers a detailed and informative look at this widely used polymer.