Silicone materials are highly active adsorbent materials and belong to amorphous substances.

I. Chemical Composition and Structure

The main component of silicone materials is silicon dioxide (SiO₂). They have stable chemical properties. They are substances with a porous structure generated through a series of complex processes such as aging and acid leaching by the reaction between sodium silicate (water glass) and sulfuric acid or hydrochloric acid. This porous structure endows them with a huge specific surface area, enabling them to adsorb a large amount of substances.

II. Physical Properties

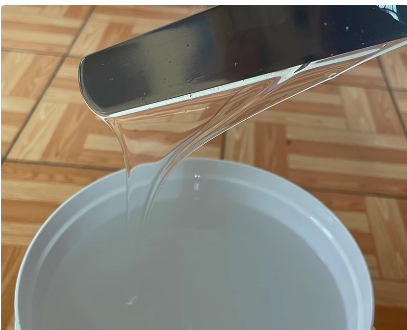

Appearance: They usually appear in the form of transparent or translucent granules or blocks, with a texture similar to that of jelly. The color can be colorless and transparent, or slightly white, beige, etc. due to the presence of impurities and other factors.

Hardness: Silicone materials are relatively soft and have a certain degree of elasticity. Their hardness is much lower than that of many metals and hard plastics, but their fluidity is much less than that of liquids, and they can maintain their own shape.

Density: The density of silicone is generally around 1.1 – 1.3g/cm³, which is relatively light, so that it will not bring excessive burden to the carrier in many application scenarios.

Thermal stability: Silicone materials have good thermal stability and can keep their physical and chemical properties basically unchanged within a wide temperature range. Generally, they can withstand temperatures ranging from – 40℃ to about 230℃. Under some special formulations, their temperature resistance range can be further expanded.

III. Adsorption Performance

The adsorption of silica gel is mainly physical adsorption. Its porous structure enables it to adsorb a variety of substances, such as water vapor, organic solvents, gas molecules and so on. For example, in moisture-proof packaging, silica gel can absorb the moisture in the air to prevent products from getting damp. Its adsorption capacity will be affected by factors such as temperature, humidity, and the properties of the adsorbed substances. In an environment with low temperature and high humidity, the adsorption amount of silica gel for water vapor usually increases.

IV. Classification

Classification by Pore Size

- Macroporous silica gel: The pore size is generally greater than 50nm. It is mainly used for adsorbing larger molecules or as a catalyst carrier and has important applications in the separation and purification processes of some macromolecular compounds.

- Mesoporous silica gel: The pore size is between 2 – 50nm. This type of silica gel has good adsorption performance for medium-sized molecules and plays a role in the slow-release systems of certain drugs, for example.

- Microporous silica gel: The pore size is less than 2nm. It is often used for adsorbing small molecular gases, such as hydrogen and nitrogen.

Classification by Use

- Industrial silica gel: It is mainly used for operations such as adsorption, drying and separation in the industrial production process. For example, it is used for the dehydration and drying of oil products in the petrochemical industry and for removing impurities and moisture in natural gas treatment.

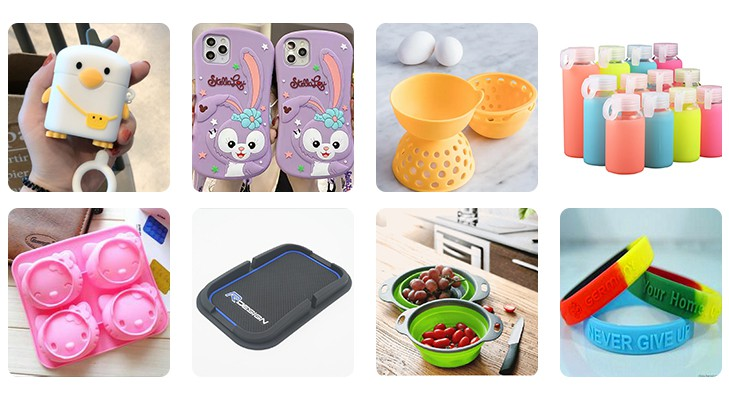

- Food-grade silica gel: This kind of silica gel complies with food safety standards, is non-toxic and odorless. It is often used in food processing, packaging and preservation. For example, it is used to make silica gel molds for foods like chocolates and ice cubes, and is also used as a food desiccant.

- Medical silica gel: It has good biocompatibility and causes little irritation to human tissues. It is used in medical devices. For example, silica gel catheters can be left in the human body for a long time for infusion, drainage and so on. It is also used in the field of plastic and cosmetic surgery, such as silicone breast augmentation prostheses.

V. Application Fields

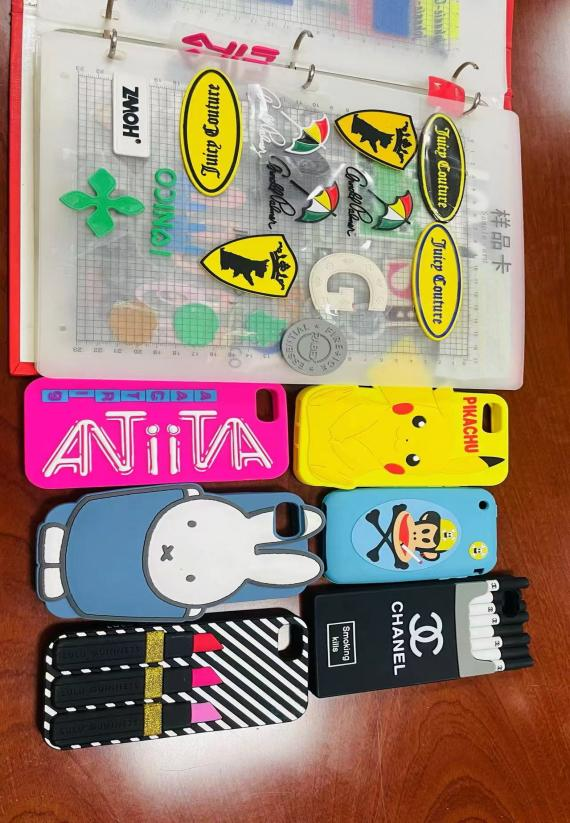

In the field of electronics and electrical appliances: Due to its good insulation and moisture-proof properties, silica gel can be used as an encapsulation material for electronic components, protecting them from the influence of the external environment and prolonging their service life. For example, it is applied to the encapsulation of some chips on computer motherboards and the protection of internal components of mobile phones.

In the field of household products: There are common silica gel kitchen utensils, such as silica gel spatulas and silica gel baking molds. These kitchen utensils are favored by people because of the characteristics of silica gel, such as high temperature resistance, softness and non-stickiness. Meanwhile, silica gel is also used to make household sealing materials, such as door and window sealing strips, which can play a very good role in sound insulation, heat insulation and sealing.

In the automotive industry: During automobile manufacturing, silica gel is used in the sealing system of automobiles. For example, the sealing gaskets in the engine compartment can prevent dust, water and oil stains from entering the engine compartment and also have a certain effect of shock absorption and noise reduction. It is also used in automobile interiors. For instance, the steering wheel covers made of silica gel can provide a comfortable feel.