Key Takeaways

Understanding the elements that contribute to effective hat label production is crucial for manufacturers looking to enhance their operational efficiency. Hat label making machines are pivotal in this process, where their advanced functionalities help streamline production. Integrating innovative technologies, such as embossing machines and 3D silicone embossing machines, can significantly elevate the quality of labels. Furthermore, being informed about the silicone embossing machine price can aid in cost-effective budgeting when upgrading machinery. Utilizing various types of label embossing machines allows for versatility in design and application, ensuring that manufacturers can create unique labels that stand out.

To minimize waste during production, investing in equipment capable of precise operations is essential. Implementing techniques such as accurate cutting and efficient alignment can substantially reduce material wastage. Consistency in using high-quality materials with your embossing machine leather will lead to better output quality and durability. Engaging with industry experts can also provide valuable insights into best practices for ensuring quality.

“> Tip: Regular maintenance of your equipment, including embossed printing machines, will help sustain performance over time.” This proactive approach not only enhances product output but also extends the lifespan of your machinery, ultimately contributing to greater production efficiency and profitability in the long run.

Introduction to Hat Label Making Machines

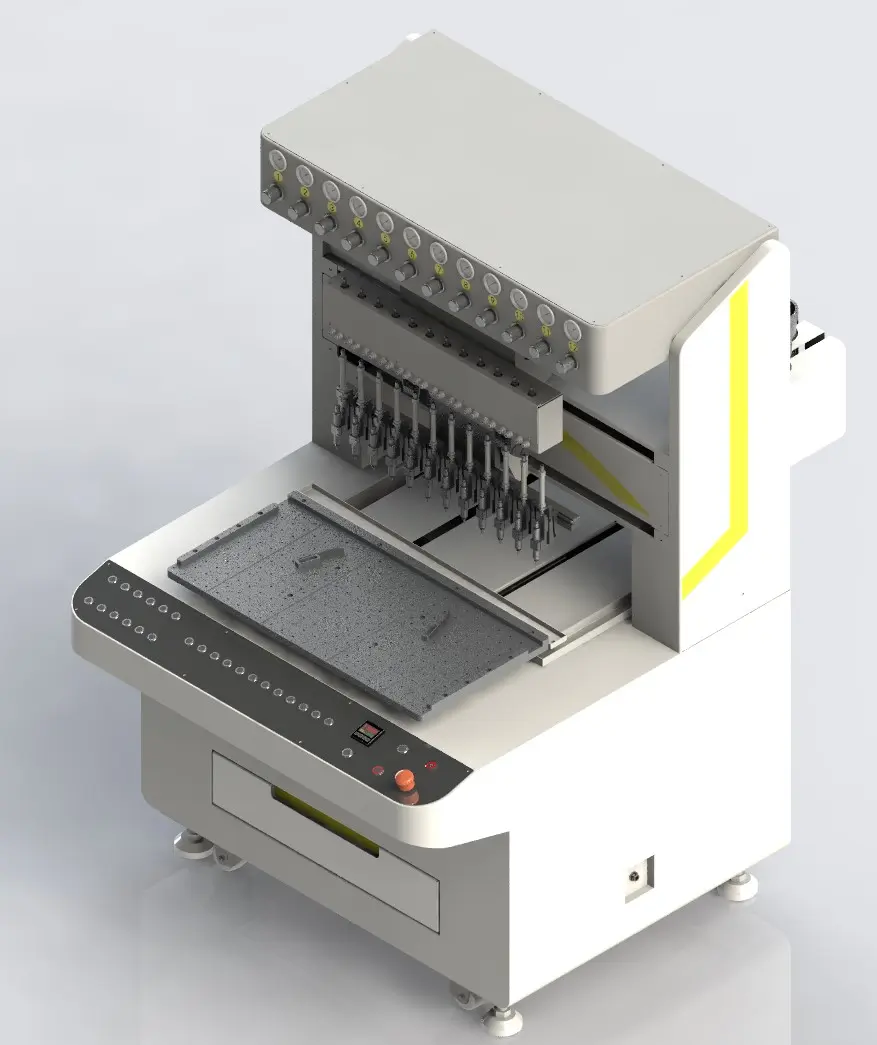

Hat label making machines play a vital role in the fashion and accessories industry, where branding and quality are paramount. These machines are designed to efficiently produce high-quality labels that adorn various hat styles, ensuring that each piece embodies the brand’s identity. Utilizing advanced embossing machines, manufacturers can create intricate designs and logos that stand out. The use of a silicone embossing machine is particularly beneficial, providing flexibility in design while managing costs effectively. Understanding the label embossing machines available on the market helps manufacturers choose the best options for their needs, considering features such as speed, durability, and the type of materials they can work with—be it fabric, leather, or silicone.

Incorporating a leather emboss machine allows for premium labeling options that are not only visually appealing but also long-lasting. Different technologies such as embossing machine leather or 3D silicone embossing machines offer unique features that can elevate a product’s marketability. Additionally, being informed about the silicone embossing machine price helps businesses budget effectively while optimizing their production capabilities. Every innovation in hat label production not only enhances productivity but also supports sustainability by reducing waste and ensuring that labels are produced with minimal impact on resources. Understanding these elements is crucial for any entity involved in hat manufacturing and labeling, ensuring quality branding with each label produced.

Key Components of Efficient Hat Label Production

When producing high-quality hat labels, understanding the key components of the process can significantly impact efficiency and effectiveness. One critical element is the use of an embossing machine, which plays a vital role in creating textured labels that enhance the overall appeal of the hats. A variety of machines are available, including silicone embossing machines and label embossing machines, which are designed to produce detailed engravings and impressions on different fabric types.

The cost aspects, such as the silicone embossing machine price, should also be taken into account during production planning. Selecting the right machine not only ensures fabulous designs but also impacts productivity. For instance, using a leather emboss machine can provide durable and aesthetically pleasing labels, particularly for premium hats.

Incorporating an embossing machine leather option can elevate product quality while ensuring consistent output. Additionally, for those working with various materials, choosing an appropriate embossing machine fabric is essential for achieving desired results without compromising quality. Manufacturers should consider investing in advanced options like the 3D silicone embossing machine, which allows for intricate detail that may set their products apart in a competitive market.

Ultimately, integrating these components effectively contributes to a streamlined production process while emphasizing both quality and efficiency in hat label manufacturing.

Strategies to Enhance Productivity in Label Manufacturing

In the fast-paced world of hat label production, enhancing productivity is vital for staying competitive and meeting rising demand. One effective strategy is investing in state-of-the-art embossing machines. These machines play a crucial role in producing high-quality labels with precision and speed. For instance, a silicone embossing machine can create intricate designs that add value to your products while also maintaining efficiency. Furthermore, understanding the silicone embossing machine price relative to its capabilities can help manufacturers make informed purchasing decisions that maximize their return on investment.

Utilizing advanced label embossing machines ensures consistency and reduces errors, which ultimately leads to less waste and higher output. Incorporating a leather emboss machine into the production line can expand product offerings, catering to diverse market segments and increasing profitability. For those focusing on textiles, an embossing machine fabric can effectively create standout labels tailored for various materials.

Additionally, investing in newer technologies such as a 3D silicone embossing machine enhances the visual appeal of labels, making them more attractive to consumers. Streamlining operations by automating certain aspects of the label-making process with an embossed printing machine not only speeds up production but also allows for better resource allocation. By implementing these strategies, manufacturers can significantly boost their productivity while ensuring that quality is never compromised.

Waste Reduction Techniques for Hat Label Production

In the competitive world of hat manufacturing, implementing effective waste reduction techniques in hat label production can lead to significant cost savings and environmental benefits. One effective approach is to utilize advanced embossing machines specifically designed for creating high-quality labels efficiently. By investing in a silicone embossing machine, manufacturers can reduce material waste associated with traditional printing methods, as these machines often require fewer resources to produce durable and visually appealing labels. Additionally, understanding the silicone embossing machine price in relation to its long-term benefits can help businesses make informed purchasing decisions that enhance their production efficiency.

Moreover, introducing label embossing machines that can work with various materials such as fabric and leather further minimizes scrap. The adaptability of these machines allows them to create custom labels without the need for excessive trial runs, which often lead to wasted materials. Furthermore, using a 3D silicone embossing machine can create intricate designs that enhance product appeal while still maintaining efficiency in the production process.

Training staff in the operation of these innovative devices also contributes to waste reduction. Educated operators are better equipped to manage and optimize production flow, reducing errors that lead to wasted materials. By incorporating techniques such as real-time monitoring of material usage and experimenting with different sizes for labels with a label embossing machine, companies can significantly cut down on excess fabric or leather scrap.

In summary, by integrating modern technology like embossed printing machines into label production processes and focusing on training personnel in best practices, businesses in the hat industry can effectively minimize waste while ensuring high-quality output. This not only helps maintain competitive pricing but also aligns with growing consumer demand for sustainable manufacturing practices.

Ensuring Quality in Hat Labels: Best Practices

Quality assurance in hat label production is paramount to meet consumer expectations and enhance brand reputation. Companies should employ an effective embossing machine to guarantee that the labels not only withstand wear and tear but also maintain clarity and visibility over time. A variety of label embossing machines are available, with specialized options like the silicone embossing machine suitable for softer materials, ensuring that the embossed designs are not only attractive but also durable.

To optimize production efficiency while maintaining high quality, businesses must consider the most appropriate machinery based on their specific needs. For example, utilizing a leather emboss machine can enhance the texture of labels made from leather materials. Furthermore, businesses should regularly price-check various options such as silicone embossing machine price to find a cost-effective choice without compromising quality.

Implementing rigorous inspection protocols post-production is another essential practice for ensuring quality. Using an embossed printing machine, for instance, can ensure a uniform application of designs across large batches, reducing discrepancies. Additionally, investing in advanced technologies like the 3D silicone embossing machine can offer unique design capabilities that appeal to consumers aesthetically.

The table below outlines some best practices for maintaining high-quality standards in hat label manufacturing:

By adhering to these best practices and utilizing advanced machinery like embossing machines, manufacturers can significantly enhance the overall quality of their hats’ labels, paving the way for greater customer satisfaction and brand loyalty.

Expert Insights on Improving Operational Efficiency

Improving operational efficiency in hat label production is crucial for manufacturers aiming to remain competitive in the market. One innovative approach is the integration of advanced embossing machines into the production line. These machines can significantly enhance the quality of labels by providing intricate designs and durable textures, which are critical for branding. Manufacturers should consider investing in a variety of label embossing machines, including options specifically designed for fabric, leather, and silicone applications, such as the 3D silicone embossing machine.

When selecting an embossing machine, factors like the silicone embossing machine price and compatibility with different materials—such as leather with a leather emboss machine—must be evaluated to maximize productivity while keeping costs manageable. Utilizing a blend of traditional and modern techniques can help streamline operations, reduce waste, and produce high-quality labels that meet consumer expectations. This holistic approach not only saves time during production but also enhances product durability and aesthetic appeal.

To further streamline processes, manufacturers can adopt smarter workflows that utilize technology for tracking production metrics. Automation tools provide real-time data, allowing adjustments to be made quickly to maintain efficiency. In addition, collaboration with suppliers who specialize in equipment like embossed printing machines can lead to insights on optimizing label creation processes and improving material sourcing.

Overall, marrying advanced technology with strategic planning will yield significant gains in operational efficiency for hat label making industries.

Future Trends in Hat Label Making Technology

As we look ahead in the realm of hat label making technology, several advancements are poised to reshape the landscape. One notable trend is the increasing adoption of embossing machines, which offer precision labeling that enhances both aesthetics and durability. The demand for label embossing machines is rising, driven by the fashion industry’s requirements for unique and customized branding. Innovations such as the 3D silicone embossing machine are gaining traction, facilitating intricate designs that stand out in a crowded market. Moreover, manufacturers are exploring cost-effective solutions, including advancements in silicone embossing machine price, which help in reducing production costs while maintaining quality.

Sustainability is becoming a priority, leading to the development of eco-friendly materials compatible with embossed printing machines. Such materials not only appeal to environmentally conscious consumers but also contribute to reducing waste throughout the production cycle. The integration of automation and smart technology in leather emboss machines is expected to make processes more efficient, decreasing time and labor costs while improving output quality significantly.

In addition to these technological innovations, there is a growing emphasis on training staff to operate high-tech equipment effectively. Investing in employee skills ensures smooth transitions when employing new machines, such as embossing machine fabric that adds versatility within production lines. By leveraging these future trends, companies can enhance their operational efficiency and responsiveness to market demands, setting a strong foundation for sustained success in hat label production.

Conclusion

In the realm of hat label production, leveraging advanced techniques and innovative technologies can significantly transform operational efficiency. As manufacturers explore the integration of various equipment, options like the embossing machine can offer unique benefits. For instance, with a leather emboss machine, producers can achieve intricate designs that elevate the appeal of their labels. The selection and understanding of label embossing machines become paramount, particularly when considering factors such as silicone embossing machine price, which can influence purchasing decisions.

Moreover, industries are increasingly adopting more versatile options like the 3D silicone embossing machine, capable of producing vibrant and detailed embossed designs on a variety of materials. Such innovations in embossing machine fabric applications not only enhance aesthetic quality but also improve durability—an essential trait for hat labels. Ultimately, focusing on incorporating state-of-the-art equipment will enable manufacturers to remain competitive while ensuring high-quality products that meet consumer demands. As these technologies continue to evolve, staying informed about emerging trends will be crucial for future success in the hat label making industry.

FAQs

What is a hat label making machine?

A hat label making machine is a specialized device used to produce labels for hats, utilizing various techniques such as embossing, printing, and cutting.

How does an embossing machine work?

An embossing machine applies pressure to create raised designs or text on the label material, which can include fabric, leather, or silicone. This creates a three-dimensional effect that enhances the quality of the labels.

What are the key components of an efficient hat label production setup?

Key components include an embossed printing machine, an efficient workflow system, and high-quality material to ensure that the label embossing machines operate effectively.

What factors influence silicone embossing machine price?

Factors influencing the price of silicone embossing machines include their functionality, material capacity, and additional features such as automated controls and speed options.

Can I use a leather emboss machine for fabric labels?

Yes, a leather emboss machine can be used for some fabric labels; however, ensure compatibility with your materials to achieve the best results.

What are some waste reduction techniques in hat label production?

To reduce waste in hat label production, implement effective layout planning, optimize cutting patterns on materials like silicone or fabric, and utilize scrap materials creatively.

How can I ensure quality in my hat labels?

To maintain high-quality standards in your hat labels, use quality materials such as durable fabrics or leather. Regularly calibrate your equipment like the embossing machine leather, and conduct routine quality checks throughout production.