Introduction to the Embossing Machine: Revolutionizing Socks Labeling

In the dynamic realm of sock manufacturing, the embossing machine plays a pivotal role in enhancing product branding through effective labeling. By creating raised designs and text, these machines add a touch of professionalism and aesthetic appeal to each pair of socks. With advancements in technology, manufacturers are now equipped with various types of embossing machines, including options for silicone embossing machines and leather emboss machines, each serving distinct labeling requirements. The versatility of label embossing machines allows them to create detailed impressions on various materials such as fabric and leather, ensuring that labels can withstand the rigors of daily use while maintaining visual clarity.

Investing in quality equipment can also alleviate production inefficiencies. For instance, a 3D silicone embossing machine can provide intricate designs that captivate consumers’ attention, while still being responsive to changes in production volume. Moreover, understanding the different price levels available for a silicone embossing machine price helps businesses budget effectively without compromising on quality. The ability to produce labels in different textures and impressions through an embossed printing machine also opens new avenues for creativity in sock design, allowing brands to differentiate themselves in an increasingly competitive marketplace.

Overall, the introduction of advanced embossing machines into sock manufacturing not only improves labeling techniques but revolutionizes how brands engage with their audience.

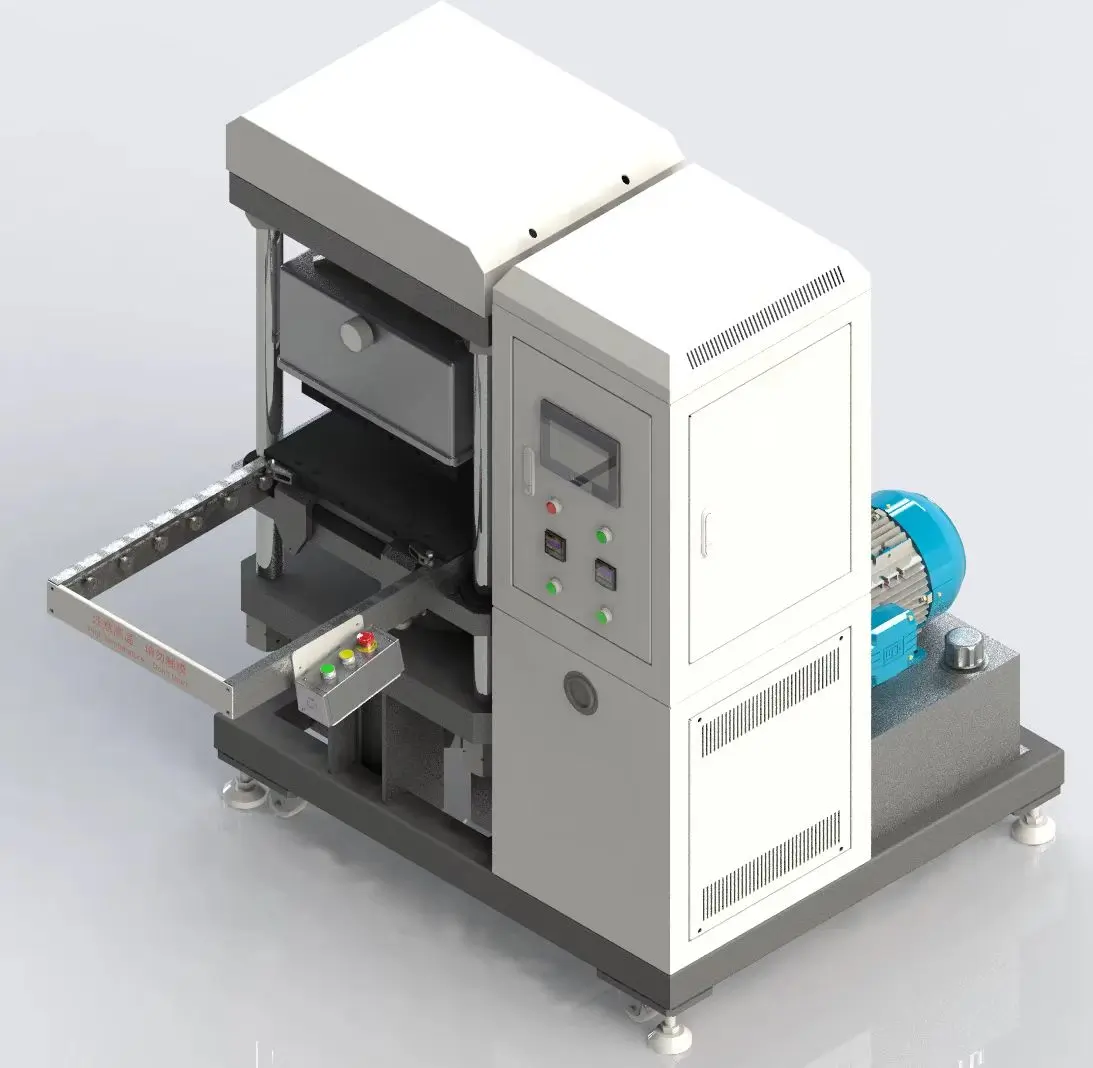

Working Principles: Mechanical vs. Hydraulic Embossing Machines

When it comes to choosing an embossing machine for label production in the socks industry, understanding the working principles of mechanical and hydraulic embossing machines is crucial. Mechanical embossing machines function through a system of gears and levers, applying pressure to create intricate designs on labels. This method is generally more straightforward, making it easier to maintain and operate for smaller-scale production runs. In contrast, hydraulic embossing machines utilize fluid power to generate significantly higher levels of force, allowing for embossed designs that require greater detail or depth. These machines are also capable of handling various materials, from embossing machine fabric to thicker materials such as leather with ease. The silicone embossing machine price often reflects the complexity and capabilities of hydraulic models versus mechanical ones; typically, hydraulic machines come at a premium due to their advanced technology and performance capabilities.

For brands focusing on quality and precision in their sock labels, investing in a robust label embossing machine may prove beneficial. The ability of a 3D silicone embossing machine to create multi-dimensional designs sets it apart from traditional methods. Furthermore, understanding how each type contributes to your production goals is essential for success in a competitive market. Whether opting for a simpler style or seeking something more advanced like the tailored features offered by an embossed printing machine, weighing the pros and cons of mechanical versus hydraulic options allows manufacturers to make informed decisions that enhance their operational efficiency.

Common Types of Embossing Machines and Their Applications in the Socks Industry

In the socks industry, embossing machines play a crucial role in enhancing brand identity and labeling. There are several types of embossing machines that cater to different materials and production needs. For instance, the silicone embossing machine is particularly useful for creating intricate designs on silicone labels, allowing manufacturers to add a unique touch to their products. When considering the silicone embossing machine price, it’s essential to weigh its capabilities against your production requirements.

Another popular option is the label embossing machine, which specializes in producing raised text or patterns on labels designed for socks. This type of machine ensures that labels withstand wear and tear while maintaining visual appeal. Additionally, the leather emboss machine provides opportunities for crafting high-end designs on leather materials, particularly for premium sock lines that target a more affluent market.

With advancements in technology, 3D silicone embossing machines have emerged, enabling manufacturers to create three-dimensional effects on labels. This innovative approach captures attention and distinguishes products on store shelves. Similarly, embossing machine fabric models allow textile manufacturers to produce unique designs directly onto fabric during production.

Overall, selecting the right type of embossed printing machine can significantly influence the quality and marketability of socks in today’s competitive industry. Understanding these different machines and their applications helps producers optimize their labeling processes effectively while catering to various consumer preferences.

Performance Comparison: Mechanical vs. Hydraulic Embossing Machines

When it comes to choosing an embossing machine for socks labeling, understanding the performance differences between mechanical and hydraulic embossing machines is crucial. Mechanical machines utilize a series of gears and levers to create pressure, making them more suited for simpler designs. They tend to be more affordable, with a lower silicone embossing machine price, which is appealing for small to medium-sized businesses venturing into socks production. On the other hand, hydraulic machines offer superior pressure control and are capable of creating intricate designs on various materials, including leather and fabric. These devices provide a precise outcome, often favored when high-quality labels are required.

For businesses that frequently switch between materials like leather and different fabrics, incorporating a label embossing machine can enhance productivity and output quality significantly. While hydraulic machines are often more expensive, their investment can result in better performance over time due to their durability and versatility with thicker materials, such as when using a 3D silicone embossing machine or an embossed printing machine.

Ultimately, the choice between mechanical and hydraulic systems depends on specific production needs, budget constraints, and the types of labels being produced. Those looking to invest in the long-term success of their socks manufacturing may find that premium features in some hydraulic models justify the higher initial cost compared to basic mechanical options like the embossing machine leather models. Understanding these differences will help businesses select the right type for achieving truly professional label quality within this vibrant industry.

Features to Consider When Choosing an Embossing Machine for Socks Labels

When selecting an embossing machine for socks labels, various features warrant attention to ensure you choose the right machine for your production needs. First, consider the type of materials you will be working with; if you’re dealing with fabrics, a dedicated embossing machine fabric may be necessary for optimal results. Also, pay close attention to the printing options available; machines with multiple functionalities can provide versatility, allowing you to experiment with styles like raised or recessed lettering. Moreover, the speed and efficiency of the machine are crucial; faster machines can significantly enhance productivity, particularly in high-demand situations.

You’ll also want to look at the price range, as this can vary widely depending on features and capabilities—researching options like the silicone embossing machine price could give you insights on what fits your budget while meeting your requirements. Another important aspect is ease of use; a user-friendly interface helps reduce training time and increases operation efficiency. For durability, consider models known for robust construction like the leather emboss machine, which often withstands more rigorous use. Additionally, if you’re looking into more advanced options, exploring machines like the 3D silicone embossing machine could yield unique labeling solutions that set your socks apart from competitors. In conclusion, evaluating these features will help streamline your decision-making process and align it with providing high-quality labels that enhance your product’s appeal in a competitive market.

Top Benefits of Using an Embossing Machine in Sock Manufacturing

Utilizing an embossing machine in sock manufacturing brings numerous advantages that can significantly enhance production quality and efficiency. One of the primary benefits is the ability to create intricate designs on labels, which adds a professional touch that distinguishes products in a competitive market. The precision of label embossing machines allows for consistent quality, ensuring that each label created is uniform and clear. Additionally, using a silicone embossing machine can be cost-effective; it often results in lower labor costs due to decreased manual handling and faster production times.

Another notable advantage is the versatility offered by these machines. For instance, a 3D silicone embossing machine can produce raised logos and text that enhance the tactile quality of socks, making them more appealing to consumers. This not only improves customer satisfaction but also helps in brand recognition. When choosing an embossing machine for fabric, it’s essential to consider the types of materials being used, as certain machines, like the leather emboss machine, are more suited for specific fabrics.

Furthermore, investing in high-quality embossed printing machines can streamline labeling processes while reducing material waste—a critical consideration for any manufacturer. By incorporating these machines into your production line, you can maintain high standards of both efficiency and sustainability.

“An effective labeling strategy not only improves your product but also nurtures customer loyalty.”

By leveraging these benefits through thoughtful selection of technology like the embossing machine leather or other specialized types suited for socks, manufacturers can meet growing demands while maintaining competitive advantage in the industry.

Conclusion: Enhancing Your Labeling Process with the Right Embossing Machine

In the dynamic world of sock manufacturing, investing in the right embossing machine can significantly elevate your production efficiency and labeling quality. By utilizing an embossing machine, manufacturers can ensure that their labels are durable and visually appealing. The market offers various options, including silicone embossing machines which are known for their versatility, and the leather emboss machine which excels in creating labels from thicker materials. When considering a purchase, understanding the silicone embossing machine price is crucial, as it can vary based on features and capabilities.

Additionally, exploring different types of label embossing machines is essential for determining which best fits your operational needs. For instance, an embossing machine for fabric allows for more delicate applications, ensuring that labels maintain their integrity during washing and wearing. Moreover, the use of a 3D silicone embossing machine can add a unique texture to labels that sets a brand apart in a crowded market.

Ultimately, selecting an appropriate embossed printing machine not only enhances product presentation but also strengthens brand identity. With various models available—from compact versions suitable for small businesses to larger industrial units designed for high-volume production—finding the right one will contribute to streamlining your labeling process while improving overall product appeal.

Conclusion: Enhancing Your Labeling Process with the Right Embossing Machine

In today’s competitive socks industry, selecting the right embossing machine can significantly enhance your labeling process. Whether you opt for a mechanical or hydraulic variant, each type offers unique features that cater to specific manufacturing needs. For instance, silicone embossing machines have become increasingly popular due to their versatility and ability to produce high-quality labels with intricate designs. The leather emboss machine, on the other hand, is ideal for manufacturers seeking durable labels capable of withstanding wear and tear. When evaluating options, it’s essential to consider the silicone embossing machine price, as this can directly impact your budget without compromising quality.

Furthermore, understanding the differences in performance and capabilities between various label embossing machines can aid in making an informed decision. Embossing machine fabric variants are perfect for those focused on textile applications, ensuring that labels are affixed securely while maintaining an appealing aesthetic. For businesses aiming for a three-dimensional effect, a 3D silicone embossing machine offers innovative solutions that can make labels stand out in a crowded marketplace.

Ultimately, whether you invest in an embossed printing machine for high-volume production or a specialized model like an embossing machine leather, the right equipment will streamline your operations and elevate your brand’s presence in an ever-evolving market.

FAQs

What is an embossing machine used for in the socks industry?

An embossing machine is utilized to create raised designs and text on socks labels, enhancing their visual appeal and providing important information.

How does a silicone embossing machine differ from a traditional embossing machine?

A silicone embossing machine is designed specifically for flexible materials like silicone, offering precision and flexibility compared to traditional metal-based machines.

What should I consider when looking at silicone embossing machine prices?

When considering silicone embossing machine prices, factor in the features, durability, versatility for different materials like fabric or leather, and the warranty provided by the manufacturer.

Can leather be embossed using an embossing machine?

Yes, a specialized embossing machine leather can create detailed patterns on leather, making it a popular choice for those looking to customize products.

What types of materials can be used with an embossed printing machine?

An embossed printing machine can work with various materials including fabric and leather, allowing for creative designs on socks labels.

Are there different types of label embossing machines available?

Yes, there are multiple types of label embossing machines, including mechanical and hydraulic options suited for different production scales and label complexities.

Remember that investing in an effective embossing machine, whether you’re using it for fabric or other materials like silicone or leather, can elevate your product branding significantly. If you’re interested in enhancing your labeling process with the right machinery, please click here: Contact Us for more information!