Key Takeaways

When diving into the world of PVC patch making machines, it’s like stepping into a magical realm where creativity knows no bounds. These machines aren’t just remarkable in their capabilities; they’re practically wizards when it comes to producing high-quality patches with ease. Imagine churning out eye-catching designs that can add flair to uniforms, bags, or promotional materials, all while sitting back and enjoying a cup of coffee. Efficiency is the name of the game here! The beauty of these machines lies in their ability to reduce production time drastically, making the entire patch-making process as smooth as butter.

Now, let’s talk applications! Whether you’re looking to outfit a sports team with custom uniforms or create memorable merchandise for an event, these machines can handle it with style. And let’s not forget the sheer joy of turning ideas into tangible products – that “Eureka!” moment when a design transforms into a vibrant patch is practically worth its weight in gold. So, strap on your creative goggles and get ready to witness the wonders a PVC patch making machine can unleash. From intricate logos to inspiring designs, this tool is your trusty sidekick on a quest for patch perfection!

Introduction to PVC Patch Making Machines

Have you ever wondered how those cool custom patches that adorn jackets, bags, and hats come to life? Enter the magical world of the PVC patch making machine! This nifty device is like a wizard’s wand for creative souls, allowing you to conjure up personalized patches in a breeze. Imagine a machine that turns your wild designs into durable, eye-catching creations! With its ease of use and efficiency, it’s no wonder that more and more people—whether hobbyists or businesses—are embracing this technology.

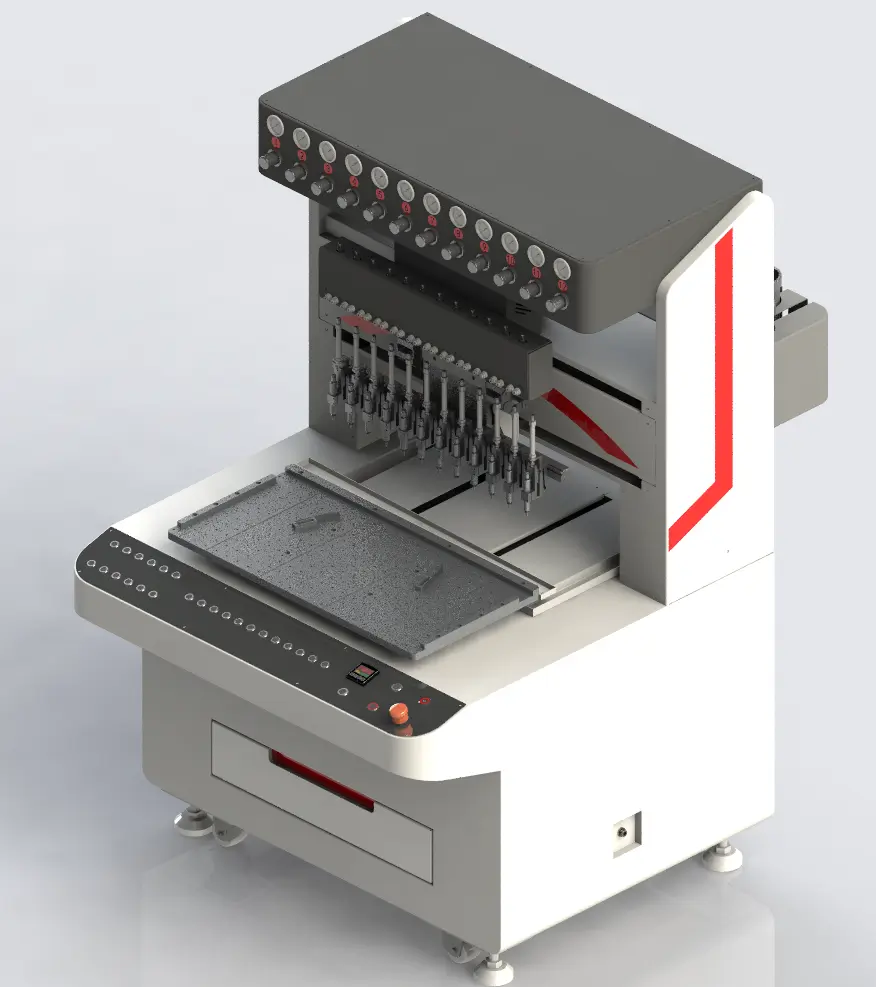

But let’s take a step back… what exactly is this machine? Picture a compact unit that does all the heavy lifting—melting and molding PVC material into stunning shapes and vibrant colors. It’s akin to being a sculptor where the clay is replaced with colorful plastic that can withstand everything from showers to mud puddles.

Using a PVC patch making machine isn’t just fun; it’s also practical! You’ll find it transforming industries from fashion to vehicle accessories, proving its versatility. Why settle for bland when you can add some pizzazz with custom designs? Plus, with its ability to churn out high-quality patches rapidly, the machine takes your creative vision and delivers it quicker than you can say “customization.”

Imagine having your unique brand logo or quirky art vision emblazoned on practically anything. That’s what this fantastic machinery is all about—bringing your imagination to life in the most delightful way! So buckle up as we delve deeper into this fascinating subject—the adventure has just begun!

Key Features of PVC Patch Making Machines

When it comes to creating custom patches, the PVC patch making machine takes the cake—or should we say, takes the patch! These machines are like the Swiss Army knives of production; they are packed with features that make them indispensable for anyone in the customization game. First off, you’ll be amazed by their ability to produce patches in various shapes and sizes. Whether you’re looking for a classic rectangle or a quirky custom design, these machines can handle it all. Next up is speed—these machines are incredibly efficient, churning out your patches faster than you can say “supercalifragilisticexpialidocious.” Additionally, they offer precise control over color mixes and textures, allowing creators to produce vibrant designs that pop louder than a party balloon at a surprise birthday bash! And let’s not ignore durability; PVC patches are known for their resistance to water and fading. Ever tried getting a patch wet? It’s like trying to save your sandwich from a rainstorm—needless to say, durability matters! With an intuitive user interface that even your tech-challenged uncle would find easy, setting up designs is straightforward. So there you have it—a glimpse into why these magic machines are transforming how industries think about customization and creativity—the reality is more fun than fiction when it comes to PVC patch making!

Benefits of Using PVC Patch Making Machines in Production

Using a PVC patch making machine can truly revolutionize the workflow in production environments, and here’s why! First off, these machines are designed to offer superior efficiency. They can rapidly produce a variety of patches without sacrificing quality—imagine churning out high-quality custom designs faster than you can say “fashion statement!” Moreover, the materials utilized in these machines result in highly durable patches that stand the test of time. So if you’re looking to create items that can endure all sorts of adventures—like your friend’s dog who loves to roll in mud—this is the way to go.

From an aesthetic standpoint, PVC patch making machines allow for incredible customization. You’re not just limited to one design; with inventive programming and a splash of creativity, you can morph patches into walking pieces of art! Whether it’s for promotional merchandise, uniforms, or even fashion accessories, these little wonders shine brightly across various industries.

Let’s not forget about their ability to minimize waste. By efficiently utilizing materials, these machines trim down costs and maintain an eco-friendly approach—green production never looked so good! In summary, incorporating PVC patch making machines into your production line isn’t just about keeping up; it’s about leaping forward into a land where creativity meets efficiency. So why not dive in and spark some patch-making magic?

Applications Across Various Industries

When it comes to the versatility of the PVC patch making machine, it’s like a superhero in the world of manufacturing—ready to save the day across various industries. From fashion to military, these machines have a knack for producing custom patches that are not only durable but also visually stunning. In the apparel industry, trendy brands utilize them to create eye-catching designs that make their products more appealing. Meanwhile, in the outdoor adventure sector, these patches are stitched onto bags and gear, assuring adventurers that their gear is not only functional but also stylish.

And don’t forget about the sports teams; they rely heavily on PVC patches for jerseys and uniforms, turning average players into instant stars with vibrant team logos and personalized flair. Even in corporate settings, companies are hopping on the bandwagon by customizing patches for employee uniforms or promotional giveaways—making brand visibility more fun! With such a broad range of applications, one can confidently say that the PVC patch making machine isn’t just a piece of equipment; it’s an essential tool that breathes life into creativity across industries! So whether you’re looking to make your mark in fashion or simply want to jazz up some old gear, this machine is quite literally your best patch!

The Process: How a PVC Patch Making Machine Works

Have you ever wondered how those eye-catching PVC patches come to life? It’s like cooking, but instead of gourmet ingredients, we’re blending polymer materials and digital wizardry. The first step in the process is to design your patch, which can be accomplished using computer-aided design (CAD) software. This is where artists flex their creative muscles and create visually stunning designs that can range from intricate patterns to simple logos. Once the design is perfected, it’s time to roll up those sleeves and let the PVC patch making machine do its job.

These machines use heat and pressure to bring the designs out of the digital realm and into the physical world. The PVC material is loaded into the machine, and as it heats up, it becomes pliable and ready for shaping. Then, the magic happens: a mold forms around the heated PVC, capturing every detail of your design like a snapshot in time. After a brief cooling period—during which you might want to grab a snack (or two)—the patch solidifies into its final form.

But it’s not just about slapping hot plastic into a mold; this process also involves an array of colors that make those patches pop! By layering different colors of PVC, machines can create multidimensional masterpieces that catch every eye in sight. Finally, once they cool down completely, workers carefully remove each patch from its mold—it’s like unwrapping gifts on your birthday, only better!

Overall, this process combines technology with artistry in such a fun way that it feels less like work and more like an exciting DIY project on steroids! Who knew making PVC patches could be so enthralling? So next time you see one of these beauties adorning someone’s backpack or jacket, remember there’s a fascinating journey behind its creation!

Tips for Choosing the Right PVC Patch Making Machine

When you’re on the hunt for the perfect PVC patch making machine, it’s easy to get bogged down by features that sound fancy but don’t really make a difference. Here’s a tip: focus on what matters most! First, consider the production capacity. If you’re planning to produce patches as fast as a caffeinated squirrel on a treasure hunt, you’ll need a machine that can keep pace with your creativity. Next, think about the design flexibility of the machine—can it handle intricate designs or is it more of a “keep it simple, silly” kind of device? Look for machines that allow you to adjust settings easily to create both charmingly simple patches and detailed specialty pieces.

Don’t overlook the durability of the machine itself; after all, you want something that stands the test of time and isn’t prone to meltdowns like an overcooked dinner! Customer reviews can also provide insight into how well machines perform in real-world settings. A highly-rated model will often save you from buyer’s remorse and endless mechanical headaches. Lastly, consider your budget: there’s no need to break your piggy bank to find a solid machine; balance cost with features—after all, you want something that’ll help create quirky patches without emptying your wallet faster than a magician’s rabbit! So keep these tips in mind and get ready to embark on your glorious patch-making journey!

Streamlining Custom Patch Production: Best Practices

When it comes to custom patch production, efficiency can make all the difference. Having the right PVC patch making machine is akin to having a magic wand that transforms ideas into tangible, stylish patches with ease. To kick things off, keep your workspace organized—trust me, no one wants their creativity interrupted by a game of “Where did I put that?” Next, ensure that you have sufficient supplies of PVC materials, as running out mid-project can bring your patch party to an abrupt halt. Speaking of parties, or rather production runs, timing is essential. Utilizing automation features in your PVC patch making machine not only speeds up production but also ensures uniform quality—no one wants patches that look like they went through a funhouse mirror! Experimentation is another key player in this game; try out different designs and settings to see what creates the most striking results. And let’s not forget about maintenance; keeping your machine squeaky clean is crucial for prolonging its life and preventing hiccups in your high-speed patch production line. By embracing these best practices, you’ll find yourself producing remarkable patches faster than you can say “custom orders”!

Future Innovations in PVC Patch Making Technology

As the world of manufacturing continuously evolves, the PVC patch making machine industry is not one to lag behind. Innovations are around every corner, and with them comes a splash of creativity that keeps things interesting! Imagine waking up to find that your trusty PVC patch making machine has transformed into a high-tech gadget straight out of a sci-fi movie. Manufacturers are exploring smart technology to create machines equipped with Artificial Intelligence, allowing for real-time adjustments and predictive analytics. This means your patches could be produced faster and with precision that would make a laser printer envious!

Moreover, advancements in sustainable materials are making waves, allowing for the use of eco-friendly PVC alternatives that’ll keep Mother Earth smiling while you sew. Enhanced customization features promise to be a game-changer as well, offering options for intricate designs that can be integrated right into the production process. So why settle for standard when extraordinary is just around the corner? The future holds a delightful mix of speed, sustainability, and creativity—making DIY enthusiasts cheer while setting the stage for businesses to stand out in an increasingly competitive market. Buckle up; it’s going to be an exciting ride in the world of PVC patch making technology!

Conclusion

In summary, investing in a PVC patch making machine can revolutionize the way custom patches are created, ensuring both efficiency and quality that can withstand the test of time—or at least a toddler’s sticky fingers. These machines are like the superheroes of the patch world, swooping in to save the day with their incredible ability to produce high-quality patches at breakneck speed. Whether you’re binding souvenirs for a triathlon or customizing patches for a fashion line, these machines are equipped with features that make production a breeze. From high-speed printing to user-friendly interfaces, they transform complicated processes into simple tasks that even your pet goldfish could fathom—well, maybe not. As industries from sports teams to corporate branding adopt this technology, we’re likely to witness innovative adaptations that will keep this machinery relevant and on-trend. So, whether you’re serious about patch production or just want to impress your friends with your newfound skill in PVC artistry, diving into the world of PVC patch making machines is bound to bring joy, creativity, and maybe even a little laughter to your workspace!

FAQs

What is a PVC patch making machine?

A PVC patch making machine is an innovative piece of equipment designed to produce flexible, durable, and customizable patches using polyvinyl chloride materials. It can create designs and logos with great precision, perfect for various applications.

How does a PVC patch making machine work?

This machine typically combines processes like molding, cutting, and printing. The design is created digitally, then transferred to a mold where the PVC material is heated and shaped into patches.

What types of patches can I create with this machine?

You can create a multitude of patches including embroidered patches, 3D designs, and labels. They’re great for clothing, bags, hats, and promotional merchandise!

Is it cost-effective for small businesses?

Absolutely! Once you get your PVC patch making machine, the cost of materials tends to be lower than outsourcing production. You can also produce on-demand, helping reduce waste and inventory costs.

Are PVC patches durable?

Yes! Patches made with PVC are highly resistant to wear and tear. They withstand various weather conditions and are easy to clean — perfect for outdoor gear or uniforms.

Can I customize the designs?

Of course! The beauty of using a PVC patch making machine is that you can let your creativity run wild. From colors to shapes and sizes, you have complete control over your customizations.