Key Takeaways

When diving into the world of PVC rubber patch machines, you quickly realize that they’re not just any ordinary machines—they’re the superheroes of manufacturing! Imagine a production line where efficiency zips around at supersonic speed, and there’s no need for capes. These machines bring a level of durability to the table that would make even the toughest materials jealous! Thanks to their ability to create robust patches, manufacturers can rest assured they are getting a product that will last longer than your favorite pair of old sneakers.

Customization? Oh boy, these machines deliver! From simple designs to complex logos, you can tailor your PVC rubber patches to fit any customer whim. Why settle for generic when you can have your very own original works of art? And let’s not forget about how these charming machines save you some serious cash—making them quite the wallet-friendly choice in manufacturing. With such great benefits, it’s clear that embracing a PVC rubber patch machine is not just smart; it’s a strategic move that transforms production processes and takes product quality from “meh” to “wow”! So buckle up, manufacturers; efficiency, durability, customization, and cost-effectiveness are about to take your production experience on a fun-filled ride!

Introduction to PVC Rubber Patch Machines: An Overview

Welcome to the marvelous world of PVC rubber patch machines, where manufacturing meets whimsy! Imagine a factory buzzing with the precision of a Swiss watch, only instead of gears, we have these magical machines crafting perfectly-formed rubber patches. These bad boys are designed to turn your manufacturing woes into wows, all while ensuring a sprinkle of fun in the process!

Whether you’re looking to add a splash of personality to your products or simply need something that can hold up against the trials of time (and maybe even a few unscheduled snack breaks), PVC rubber patch machines have got your back. They promise not just efficiency but also a durability that could rival even your great-aunt Edna’s fruitcake recipe — that recipe never goes bad, right? Plus, with customization options galore, you can tailor each patch to match every quirky whim or practical need you might have.

Oh! And let’s not forget about the all-important factor of cost-effectiveness. These machines won’t just save you time; they’ll save you money — leaving some extra cash for those Friday treats! When you think about how they transform production processes like piecing together an intricate puzzle (minus the frustration), it’s hard not to get excited. So come along on this patch-tastic journey as we dive deeper into how these wonder-machines are reshaping the world of manufacturing, one quirky patch at a time!

Enhancing Manufacturing Efficiency with PVC Rubber Patch Machines

Imagine a bustling manufacturing floor where machines hum a happy tune, producing high-quality goods that are as reliable as your favorite pair of socks—comfortable and ready for anything! Enter the PVC rubber patch machine, your new best friend in the manufacturing realm. This whizzy gadget doesn’t just patch things up; it revolutionizes the way products are made. First off, it ramps up efficiency to levels that even the Flash would envy. With lightning speed, this machine churns out PVC patches faster than you can say “bulk order,” leaving traditional methods in the dust. But that’s not all; its programming is so smart that it reduces waste, ensuring that every square inch of material is utilized, which makes for a happy accountant too!

Now, let’s talk about durability—just like your favorite superhero, this machine is built to last. It withstands the wear and tear of daily use while producing patches that can endure even the craziest adventures—perfect for everything from jackets to decorative items. And customization? Oh boy! The PVC rubber patch machine allows manufacturers to let their creativity run wild with unique designs and colors tailored to every customer’s whim. It’s like having a magic wand that transforms ordinary patches into extraordinary masterpieces! In essence, this piece of equipment doesn’t just enhance manufacturing efficiency; it’s an enchanting blend of speed and reliability that empowers companies to meet demands with flair, saving time and money while raising their product quality to soaring heights!

Longevity and Durability: Why PVC Rubber Patches are More Reliable

When it comes to manufacturing, every producer is on the lookout for materials that can withstand the test of time. PVC rubber patches might just be the superheroes of the patch world, and here’s why! First off, these patches are not just pretty faces. They boast incredible resistance to elements like water and sunlight, making them perfect for outdoor gear. Think about it: no one wants a patch that melts away like ice cream on a summer day!

Another reason why PVC rubber patches shine brighter than many competitors is their impressive durability. They can take a serious beating without showing signs of wear and tear. It’s like having a dog that never gets tired of playing fetch—always ready for action! In fact, many manufacturers have reported that PVC rubber patches last much longer than traditional fabric alternatives, making them an ideal choice for products meant to endure rigorous use.

Add to this the fact that they won’t easily fade or crack, retaining their vibrant colors over time. It’s as if they’ve mastered the art of aging gracefully, much like fine wine or your favorite sitcoms that never get old!

To summarize this patch paradise, here’s a quick comparison chart to illustrate why PVC rubber patches reign supreme:

| Feature | PVC Rubber Patches | Fabric Patches |

|---|---|---|

| Weather Resistance | Excellent | Moderate |

| Durability | High | Medium |

| Color Retention | Exceptional | Prone to Fading |

| Cost Over Time | Low (long-lasting) | High (replace often) |

So next time you’re considering materials for your products, remember: PVC rubber patches may not wear capes, but they sure do pack a punch in reliability!

Customization Options: Tailoring PVC Rubber Patches for Every Need

When it comes to PVC rubber patches, customization is where the magic happens! Imagine transforming a plain piece of fabric into a vibrant, eye-catching masterpiece that fits your brand like a glove. With a PVC rubber patch machine, you can unleash your creativity and design patches in virtually any shape, size, or color. Whether you need a patch shaped like a whimsical unicorn or one that proudly displays your logo in neon pink, the possibilities are endless! You can incorporate textures and even 3D elements that make your patches pop out of the crowd—literally! The process is so tailored that it’s like designing an outfit for a fashion show, but in this case, the runway is your product line. Plus, with rapid production capabilities, you won’t have to wait eons for your customized patches to arrive; it’s like having a magic wand—but instead of turning pumpkins into carriages, you’re creating trendy accessories! So whether you’re decking out jackets, bags, or hats, these customizable patches can make any item feel special and personalized. Let’s be honest; who wouldn’t want to add a dash of fun (and probably some sass) to their products? So get ready to wow your customers with unique designs that truly reflect their personality—or at least distract them from their bad Tuesdays!

Cost-Effectiveness of PVC Rubber Patch Machines in Manufacturing

When it comes to the budget-conscious side of manufacturing, PVC rubber patch machines truly shine, often grabbing the spotlight like a dancing llama at a county fair! These machines streamline the production process, which means less time fiddling around and more time focusing on getting those patches out the door. Picture this: fewer labor costs and minimized waste. It’s like finding a $20 bill in your old coat pocket—unexpected and delightful!

Moreover, the durability of PVC rubber patches translates to fewer replacements and repairs, making you feel like you’ve hacked into the universe’s money-saving system. They last longer than your favorite TV series streaming on repeat! And let’s not forget about customization—PVC rubber patch machines allow for vibrant designs that stand out without breaking the bank. Why settle for bland when your product can pop?

“In business, you either serve your purpose or serve a hefty bill.”

So, by investing in these machines, manufacturers can enjoy an efficient production cycle while keeping costs low. It’s truly a win-win situation, giving businesses more room to invest in growth rather than constantly shelling out cash for inefficiencies. So why not embrace these machines? After all, every penny saved is a penny earned—in this case, it could mean upgrading that humble coffee maker to an espresso machine!

Transforming Production Processes: The Impact of Advanced Technology

In the fast-paced world of manufacturing, technology is the superhero we never knew we needed. Enter the PVC rubber patch machine—it’s like having a magic wand that turns ordinary production processes into streamlined systems of efficiency! Imagine this machine zipping through tasks faster than you can say “customization options.” With just a flick of a switch, it can churn out patches that not only meet but exceed durability expectations. Think about it: no more patches that wear out faster than your favorite pair of socks! Plus, this nifty piece of equipment can be tailored to fit any need—whether it’s for trendy jackets or stylish caps. And just when you thought things couldn’t get better, the cost-effectiveness hits you like a surprise party—reducing waste while boosting output, leaving your budget intact for those all-important coffee breaks. So let’s give a round of applause to advanced technology for transforming the mundane into an extraordinary journey through production magic with PVC rubber patches!

Improving Product Quality with PVC Rubber Patching Solutions

When it comes to enhancing product quality, PVC rubber patching solutions are like the secret sauce that takes your manufacturing game from “meh” to “wow!” Imagine a world where your products are not just looking good but actually standing the test of time. The magic of PVC rubber patches lies in their ability to provide an exceptional level of durability and resistance against wear and tear. Say goodbye to flimsy materials that scream “cheap!” Instead, welcome a patch that can withstand the elements, from the blistering sun to the pouring rain—talk about a tough cookie!

Moreover, with customization options galore, you can give each product its own unique flair. Want neon green patches with glitter for that pop? No problemo! Need minimalist black versus white for your upscale line? Done and dusted! It’s like having an artistic license to create products that really resonate with your audience. Plus, let’s not forget about consistency; implementing these patches ensures that every item meets quality standards, so you won’t find yourself on quality control’s naughty list.

In short, using PVC rubber patching solutions elevates every aspect of product quality—making them reliable, stylish, and downright impressive! Who knew patches could pack such a punch?

Conclusion

As we wrap things up, let’s take a moment to appreciate the sheer brilliance of the PVC rubber patch machine. Picture this: a factory floor buzzing with energy and efficiency, where creativity is unleashed at the push of a button. This striking equipment doesn’t just sit there looking fancy; it transforms the mundane into the extraordinary. With its cost-effectiveness and reliability, businesses are reaping benefits like never before. Imagine tailoring your products with endless customization options, allowing your imagination to run wild – who wouldn’t want patches shaped like unicorns or space rockets? And let’s not forget its astonishing durability; these patches laugh in the face of wear and tear, standing tall against the test of time while your competitors’ patches may be left in yesterday’s fashion. In a world where efficiency meets creativity, the PVC rubber patch machine is truly the magical wand every manufacturer needs to sprinkle a little fairy dust on their production process. It’s clear; this piece of equipment isn’t just a tool; it’s a game-changer in making manufacturing not just functional but also fun! So here’s to brighter, bolder, and more imaginative patches – let’s get patched up!

FAQs

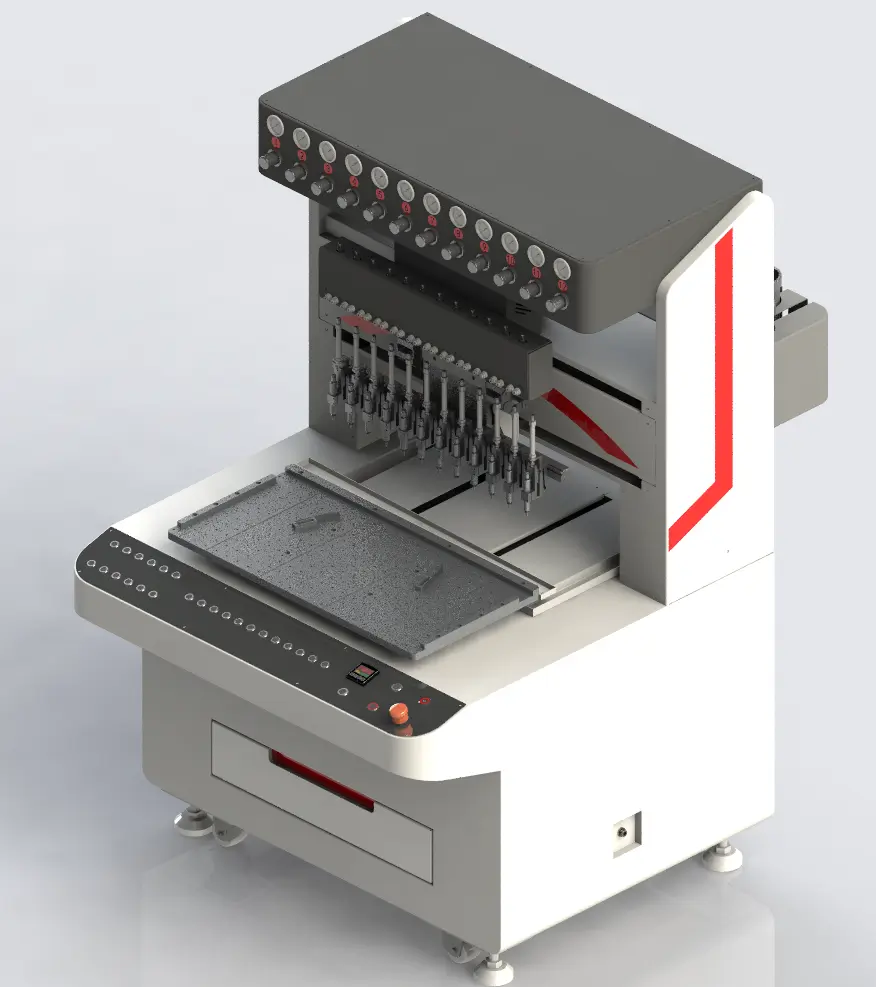

What is a PVC rubber patch machine?

A PVC rubber patch machine is a specialized piece of equipment designed to create and apply PVC rubber patches for various products. Whether for fashion, sports, or branding, this machine helps in producing durable and stylish patches that can withstand the test of time—or at least last longer than your last relationship!

What are the main benefits of using a PVC rubber patch machine?

The main benefits include enhanced manufacturing efficiency, increased durability, customizable options to fit any need, and improved cost-effectiveness. In essence, it’s like having a Swiss Army knife in your production workshop—versatile and super handy!

How do PVC rubber patches compare to other types?

PVC rubber patches are generally more reliable than fabric patches because they resist wear and tear better, even after being subjected to the harshest conditions (like that one time you forgot your jacket outside during a rainstorm!). They also maintain their vibrant colors longer, keeping your products looking fresh.

Can I customize my PVC rubber patch?

Absolutely! Customization options are plentiful. You can choose colors, shapes, sizes, and even add logos or text—perfect for those who want their products to stand out from the crowd. Think of it as dressing your product up for a fancy party!

Is investing in a PVC rubber patch machine cost-effective?

Indeed! While the initial purchase may require an upfront investment, the long-term savings gained from reducing labor costs and increasing production efficiency can make it an easy decision. Plus, fewer mistakes mean fewer tears over spilled… well, let’s just say mistakes!