How to prepare liquid PVC material?

How to prepare liquid PVC material? In the last article(Do you know what’s the liquid PVC material?), we know that liquid PVC is mixed by PVC powder, DINP oil, PVC color pigment and other some specific stabilizers.

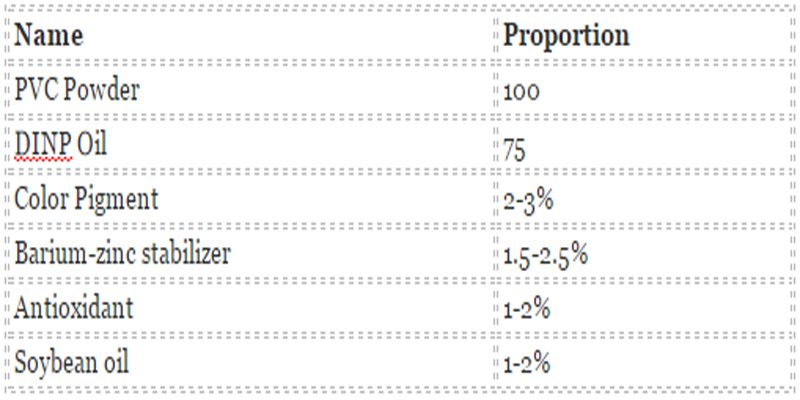

We look back our factory recipe:

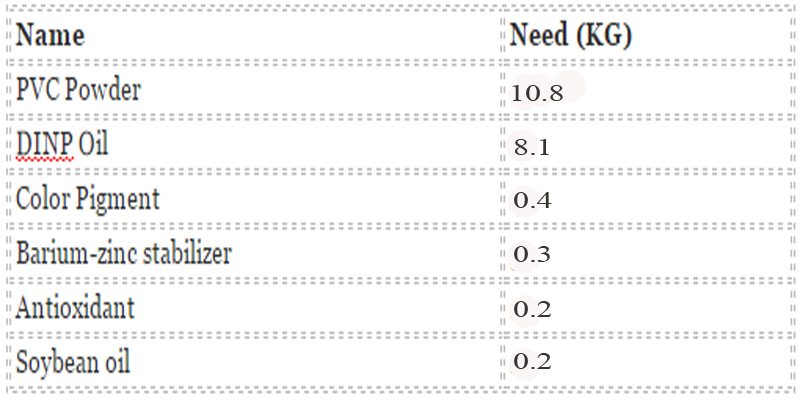

In here, we hypothesis that we prepare 20kg liquid PVC material in one time, so we need:

Mixing processing

Next, start Mixing machine, at the same time of mixing, slowly put into the 10.8kg PVC powder.

Why slowly? On the one hand, it can ensure that the powder and oil mix utter. On the other hand, it can alleviate machine pressure and protect the machine.

After 5 minutes mixing, when the powder and oil mix better, we need to add the 0.4kg color pigment, 0.3kg Barium-zinc stabilizer, 0.2kg Antioxidant and 0.2kg Soybean oil. By the way, if you asked about the quality of the products is not high, you can only add the color pigment.

Finally, continue to mix for 5 to 10 minutes.

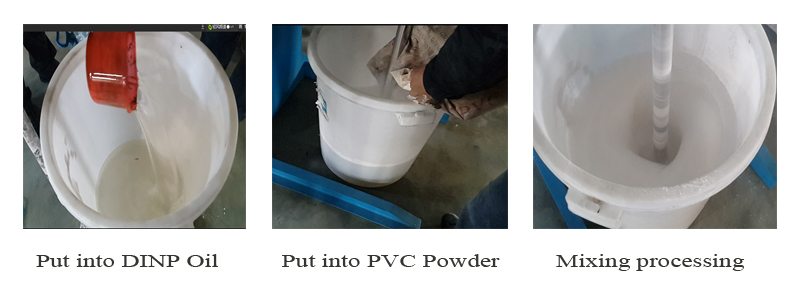

Vacuuming processing

After Mixing processing, we have got the liquid PVC material, and can use for producing. But why also need vacuuming processing?

Because in mixing processing, there is so much air in material. Although can produce processing, the end products will has a lot of bubbles, it’s unqualified. So vacuuming processing is a very important step to prepare liquid PVC material.

How to do?

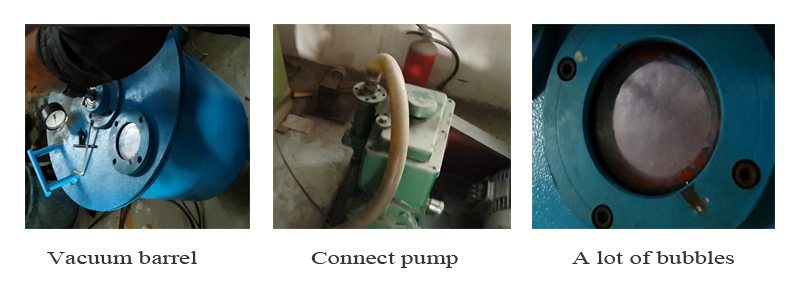

In here we need a vacuum barrel and vacuum pump. First, put the material barrel into vacuum barrel, seal and connect the vacuum pump. After the connection is verified, start.

Attention: At first, you must be careful. At the moment of vacuum pump starting, the pressure difference inside and outside is big, it will lead to a lot of bubbles, even lead to the raw material overflow from material barrel. So you need to be careful, when the bubbles is too much, you need to open the air inlet cock, but close right now. So easy!

And, also is this reason, the liquid PVC material volume shouldn’t more than 70% of material barrel, 60% is best.

The vacuuming processing usually last 15-45 minutes, it’s according to the volume and pumping speed. For example, 30kg material, 15L/S pumping speed, need 25 minutes.

Storage and use

After vacuuming processing, we have got the final material. Now you can storage, also can use to producing.

For storage, in our factory(Zhenying Machinery), usually sealed storage in vacuum barrel, can keep several years. But need sealed storage in shady and cool place and cannot to move it violently. If won’t sealed storage, it’s best to use it at the same day.

For producing, there is a note that you should pour the material into machine barrel slowly, too. That everything is in order to prevent the air into the raw material again.

That’s all. If you want to learn about the Mixing machine, Vacuum machine, you can visit our website. We are a leading manufacturer of PVC & silicone products making machine, have more than 20 years. Our main machine is PVC products making machine, Car mat making machine and Silicone products forming machine.

(Vixen wang)