Key Takeaways

Socks label making machines play an essential role in the production of stylish and functional labels. By investing in advanced machinery such as an embossing machine or a leather emboss machine, manufacturers can ensure their labels are both durable and visually appealing. The silicone embossing machine price is often justified by the quality and precision it brings to the labeling process. Various options like label embossing machines offer flexibility, accommodating different fabric types, whether it’s cotton, wool, or synthetic materials. Furthermore, with innovations like the 3D silicone embossing machine, businesses can create unique designs that stand out in a competitive market.

“Investing in quality labeling equipment can enhance brand visibility and consumer loyalty.”

The use of an embossed printing machine can also elevate the aesthetics of socks labels while ensuring sustainability through reduced waste. For fabric labels, employing durable techniques ensures that your branding remains intact throughout the lifecycle of the product. Carefully choosing between options such as embossing machine fabric or specific models tailored for leather can influence both style and functionality, making every label a reflection of brand identity. Understanding these key elements will significantly impact production efficiency and marketability.

Introduction to Socks Label Making Machines

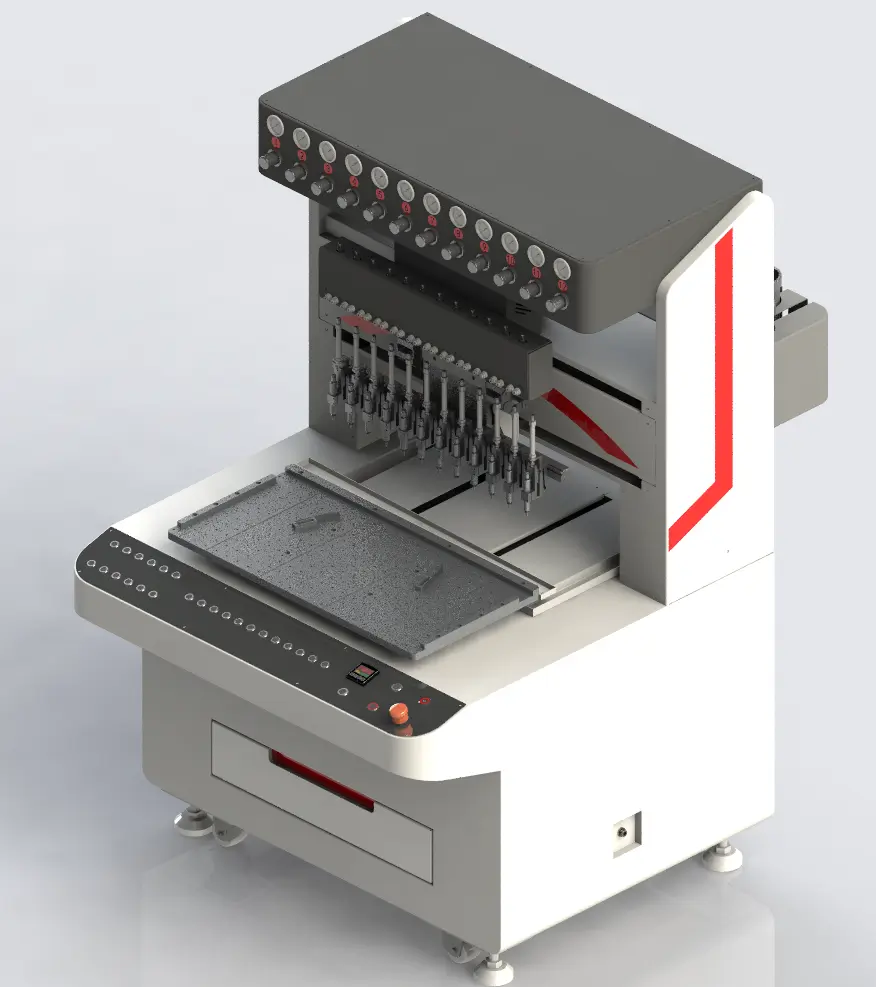

In today’s competitive textile industry, socks label making machines play a pivotal role in enhancing product visibility and streamlining manufacturing processes. These machines are designed to produce high-quality labels that can be attached to socks, ensuring that branding information is communicated effectively. The use of various technologies, such as label embossing machines, helps manufacturers create labels that are not only functional but also aesthetically appealing. A silicone embossing machine, for example, offers versatility at an accessible price point, making it an attractive option for businesses looking to combine quality with affordability.

Moreover, advanced features of modern socks label making machines allow for intricate designs and customization options. Utilizing an embossing machine leather can elevate the tactile experience of the label, as well-embossed fabrics often stand out more on retail shelves. With options for 3D silicone embossing machines, brands can transform their standard labels into dynamic marketing tools that capture consumer attention.

Investing in the right technology will not only enhance the production efficiency of sock labels but also ensure better alignment with consumer preferences for innovative label designs. As brands continue to evolve, keeping up with technologies such as embossed printing machines and different embossing machines fabric will be crucial in maintaining a competitive edge in the market.

Key Features of Modern Socks Label Making Machines

Modern socks label making machines have revolutionized the apparel industry, providing manufacturers with advanced solutions for high-quality label production. One of the standout features is the integration of embossing machines, which allow for the creation of intricate designs and textures on labels. This technology not only enhances the aesthetic appeal of socks but also contributes to brand recognition. The availability of various options, such as silicone embossing machines, offers versatility in producing labels made from different materials like fabric and leather.

When considering price points, knowing the silicone embossing machine price is crucial for small businesses aiming to balance quality and budget. High-end label embossing machines often feature advanced functioning capabilities, enabling mass production while maintaining precision in design. For instance, manufacturers can choose a leather emboss machine for creating durable labels that withstand wear and tear.

Additionally, modern socks labeling solutions utilize techniques such as 3D silicone embossing machines that produce eye-catching raised effects, enhancing product visibility in a competitive market. The blend of technology in these machines allows for seamless operation with minimal downtime, further maximizing productivity. Lastly, by incorporating user-friendly interfaces and automated processes within these modern systems, businesses can efficiently manage their socks label production while ensuring high standards are consistently met.

Benefits of Tagless Labels in the Socks Industry

In the socks industry, the shift towards tagless labels offers numerous advantages for both manufacturers and consumers. One significant benefit is enhanced comfort. Traditional labels can cause irritation or discomfort against the skin, especially during prolonged wear. By adopting tagless labels, brands can eliminate this problem, providing a more enjoyable experience for the wearer.

Moreover, tagless options allow for more extensive branding opportunities through techniques such as embossing. Utilizing an embossing machine can create subtle yet effective designs that promote brand identity without compromising comfort. The versatility of a silicone embossing machine makes it easier for manufacturers to explore creative labeling ideas that cater to various fabrics.

From a production standpoint, using tagless labels streamlines manufacturing processes. By integrating machines like label embossing machines, businesses can enhance their efficiency and reduce production time while ensuring high-quality output. The competitive nature of the socks market necessitates innovation, and investing in technologies such as a 3D silicone embossing machine or an embossed printing machine positions companies advantageously.

Additionally, tagless labels often allow for better durability when exposed to multiple washes, which is particularly relevant for socks frequently used in active settings. This durability aligns well with consumer expectations and contributes positively to brand reputation.

In summary, the use of tagless labels, supported by advanced technologies like a leather emboss machine or other types of embossing machines, significantly enhances both comfort and branding potential in the socks industry, making it a preferred choice among manufacturers striving for greater customer satisfaction and product differentiation.

The Process of Socks Label Production

The production of socks labels involves several meticulous steps that ensure high-quality and durable results. First, the design phase incorporates creative elements, including the choice of colors, logos, and text that convey the brand’s identity. Once the design is finalized, it is transferred to an embossing machine, which plays a crucial role in creating raised designs that add texture and visual interest to labels. There are various types of label embossing machines suitable for this task, each offering different capabilities tailored to specific materials like cotton or synthetic fabrics. For instance, a silicone embossing machine can achieve unique effects on softer materials while remaining cost-effective in terms of silicone embossing machine price.

Following the embossing phase, labels are cut to size using precision methods that ensure uniformity across all products. This is where technologies like an embossed printing machine come into play; these machines can create intricate designs with stunning clarity and durability. Additionally, the possibility of using advanced options such as a 3D silicone embossing machine allows brands to create standout labels with three-dimensional elements that capture consumers’ attention.

Finally, after labels are applied to socks through processes like sewing or heat transferring, each set undergoes quality checks to guarantee consistency and durability in any washing conditions. The entire process ensures that consumers receive socks with high-quality labels that not only elevate aesthetics but also resonate with the brand’s commitment to quality and style.

Innovations in Socks Label Printing Technology

The socks label making machine has evolved significantly, integrating advanced technologies that enhance both functionality and efficiency. One key innovation is the adoption of embossing machines, which add a tactile quality to labels, making them more engaging for consumers. These label embossing machines utilize various methods to create distinct patterns and texts, providing brands with the opportunity to stand out with unique designs. Moreover, silicone embossing machines offer versatility in label production, allowing manufacturers to experiment with materials and finishes without compromising on quality. The silicone embossing machine price has become more accessible, enabling even smaller businesses to leverage this technology.

Another notable advancement is the introduction of 3D silicone embossing machines, which allow for intricate designs that elevate the aesthetic appeal of socks labels. By utilizing these advanced embossed printing machines, brands can achieve more personalized branding solutions, catering directly to consumer preferences. Additionally, manufacturers are now able to produce labels on different fabrics using embossing machine fabric capabilities, expanding the range of products that can have custom labels applied.

The integration of these technologies is not purely cosmetic; it also serves a functional purpose. For instance, garments crafted using a leather emboss machine create durable labels resistant to wear over time. This durability ensures that even with frequent washing and use, the labels remain intact and legible—a critical factor for maintaining brand integrity.

In conclusion, as innovations in socks label printing technology continue to emerge, businesses have an array of options at their disposal for producing high-quality labels that not only resonate with consumers but also demonstrate brand uniqueness and durability.

Choosing the Right Socks Label Making Machine for Your Business

Selecting the appropriate socks label making machine is crucial for efficiently producing high-quality labels that enhance your product’s presentation. When considering options, it’s essential to look into various features offered by modern machines, such as embossing machines and label embossing machines. The silicone embossing machine price can vary significantly based on functionality and technology, so researching different models is advisable.

You should also consider the types of materials you will use for labeling. Machines that accommodate various fabrics, such as the embossing machine fabric, can greatly improve your production flexibility. Additionally, incorporating a 3D silicone embossing machine can add unique designs to labels that appeal to consumers.

A key aspect of your decision should entail balancing cost with quality. While some machines may come at a premium price, their efficiency and durability could lead to long-term savings and enhanced productivity in your labeling process. Look into the specifications and reviews for each device; this insight can help you in comparing features effectively.

Moreover, keep sustainability in mind when choosing your socks label making machine; manufacturers that focus on eco-friendly materials may offer labels made from recycled components, aligning with modern consumer preferences for environmentally conscious products. By weighing these factors carefully, you can make an informed decision that supports both your production needs and business goals. Here’s a comparative table summarizing some essential factors:

Sustainability in Socks Label Manufacturing

In today’s eco-conscious world, the socks label manufacturing process is undergoing a significant transformation towards sustainability. Manufacturers are increasingly focusing on environmentally friendly methods and materials to minimize their ecological footprint. The integration of embossing machines plays a crucial role in this shift. These advanced machines facilitate the efficient production of labels that are durable and visually appealing, often using recyclable materials instead of traditional synthetic options. Moreover, innovations in silicone embossing machines not only produce high-quality embossed labels but also offer a cost-effective solution for businesses, with the silicone embossing machine price being accessible for various production scales. Companies are keenly aware that using label embossing machines reduces waste by allowing for precise cutting and minimal leftover materials. Furthermore, utilizing a leather emboss machine allows brands to enhance their products with sustainable leather options, appealing to environmentally conscious consumers. The move towards using embossed printing machines can lead to reducing water usage compared to traditional printing methods, aligning with sustainable practices. A prominent trend is the development of 3D silicone embossing machines, which can create intricate designs while still maintaining eco-friendliness throughout production processes. As more brands embrace sustainable practices by selecting the right machines and materials, the socks industry can contribute positively to environmental preservation while still meeting consumer demands for quality and style.

Future Trends in Socks Labeling Solutions

As the socks industry continues to evolve, socks label making machines are adapting to meet both consumer demands and sustainability goals. One emerging trend is the use of advanced embossing machines, particularly silicone embossing machines that provide a unique tactile experience and a professional finish. These machines can emboss labels directly onto the fabric, eliminating the need for traditional tags and enhancing comfort. The silicone embossing machine price is also becoming increasingly competitive, allowing more manufacturers to adopt these technologies.

Furthermore, innovations in label embossing machines have led to greater efficiency in production, enabling businesses to produce high-quality labels quickly and at lower costs. The incorporation of features such as automated adjustments and digital controls in systems like the embossed printing machine allows for customization on-demand without sacrificing speed. In addition, manufacturers are exploring eco-friendly materials for labels that reduce waste while maintaining durability.

The demand for more personalized products is growing, prompting the development of technology that integrates with design software for real-time adjustments. This aspect of socks labeling aligns perfectly with the features found in modern 3D silicone embossing machines, which allow intricate designs to be rendered on various fabrics. As sustainability remains a priority within manufacturing processes, companies are increasingly focused on integrating these advanced technologies into their operations while minimizing their environmental footprint.

Conclusion

In the evolving world of textile production, socks label making machines play a crucial role, ensuring that every pair of socks is not just functional but also aesthetically pleasing. The advancements in label technology have introduced new possibilities, such as the use of embossing machines, which create distinct and durable labels that can withstand wear and tear. These machines include the versatility of silicone embossing machines, which offer an attractive option for brands looking to stand out, especially with options available in varying price ranges like silicone embossing machine price.

Manufacturers now have access to various types of label embossing machines, including those tailored for specific materials like leather or fabric. The leather emboss machine is particularly favored for high-end products, providing a sophisticated finish that appeals to luxury markets. Furthermore, the innovative 3D silicone embossing machine opens up new avenues for creating dynamic textures on labels. As businesses strive for sustainability and efficiency, investing in an efficient embossed printing machine helps streamline production while reducing waste.

Ultimately, staying informed about these technologies will be essential for businesses keen on enhancing their product labeling while ensuring they meet consumer expectations in quality and design. Understanding the capabilities of each machine can help manufacturers choose the right tool aligned with their brand identity and production goals.

FAQs

What is a socks label making machine?

A socks label making machine is specialized equipment designed to produce labels for socks, including tags and care instructions. These machines utilize various technologies, such as embossing machines, to create durable and visually appealing labels.

What features should I look for in a socks label making machine?

When selecting a socks label making machine, consider features like speed, versatility, and the types of labels it can produce. Advanced machines may include functions for 3D silicone embossing machine capabilities or specialized settings for embossed printing machines, enhancing creativity in your designs.

How does a silicone embossing machine work?

A silicone embossing machine utilizes a mold to create raised designs on labels. This process adds texture and depth, giving your socks tags a unique touch. The silicone embossing machines offer affordability, with competitive prices reflected in the silicone embossing machine price.

Are there benefits to using tagless labels in the socks industry?

Yes! Tagless labels can increase comfort for the wearer while allowing more room for branding on the product itself. They can be produced effectively through modern label production methods using an embossing machine fabric, ensuring durability and quality.

What is the average cost of leather emboss machines?

The price of a leather emboss machine may vary based on features and capabilities. It’s essential to compare options based on what suits your production needs best; seeking out reliable suppliers can also help you identify models that are budget-friendly while maintaining functionality.